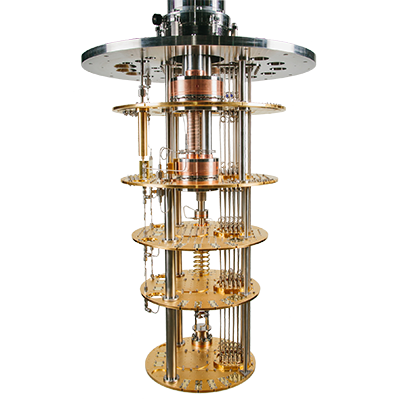

The modular Cryofree® ProteoxMX dilution refrigerator delivers greater experimental capacity and adaptability. Versatile dilution refrigerator for ULT experiments. Base temperature of < 10 mK, cooling power of > 12 µW at 20 mK and 360 mm mixing chamber plate diameter.

Dry systems do not require the use of cryogenic liquids to provide the 4 K environment. Instead, pulse tube refrigerators are used. These enable push-button operation, can reduce the cost of ownership, and negate the need for a helium liquefier.

Our Cryofree® (cryogen free) range of products provides the user with much more experimental space and a larger sample plate, due to not needing a dewar surrounding the system containing the liquid helium for cooling. Mechanical vibrations from the pulse tube refrigerator are significantly reduced using a comprehensive range of vibration isolation techniques.

Integrate microwave lines and signal conditioning hardware on the Secondary Insert for superconducting qubit development.

Integrate microwave wiring, cold electronics and superconducting magnets for spin qubit development.

Superconducting magnets and ultra low temperatures enable hall effect and quantum hall effect transport measurements.

| Base Temerature: | < 10 mK |

| Cooling Power at 20 mK: | > 12 μW |

| Cooling Power at 100 mK: | > 450 μW |

| Sample Space Diameter: | 360 mm plate |

| Line of Sight Access: | 1 x Secondary Insert (117 mm x 252 mm), 2 x KF40, 2 x KF25 |

| PTR Options: | 1.35 W, 1.50 W or 1.80 W |

| Temperature Control Range: | 10 mK to 30 K with magnet at full field |

| Magnet Options: |

Solenoid: up to 14 T Vector rotate: up to 9,1,1 T Field cancellation: < 10 mT |

For additional product information:

Contact Our Sales Team

Ideal for a multi-user or multi-experiment setting, or future-proofing the system. Side loading Secondary Inserts can be exchanged between Proteox systems enabling experiments to be set up on a workbench prior to exchange. This is a significant advantage for optical experiments where alignment of components can be performed outside of the system.

Utilise a custom Secondary Insert for an optimised experiment, ready to run on system arrival by incorporating cold electronics such as circulators and amplifiers, directly during manufacture. All mounted hardware and components are factory installed.

Explore Proteox - Watch Now

Copyright © 2025 Quantum Design Oxford